ISO 45001:2018 Occupational Health and Safety Management System

ISO 45001 is an International Standard that specifies requirements for an occupational health and safety (OH&S) management system, with guidance for its use, to enable an organization to proactively improve its OH&S performance in preventing injury and ill-health. ISO 45001 is intended to be applicable to any organization regardless of its size, type and nature. ISO 45001 enables an organization, through its OH&S management system, to integrate other aspects of health and safety, such as worker wellness/wellbeing; however, it should be noted that an organization can be required by applicable legal requirements to also address such issues.

ISO 45001 Certification – Occupational health and security the board frameworks (OHSM), is a most recent overall standard which will give a system to associations/organization to improve worker Health, wellbeing, diminish work environment inadvertent dangers and make better, secure working conditions, everywhere throughout the world.

ISO 45001:2018 will pursue the abnormal state Annex SL-structure that has been connected to other ISO Certification the board framework benchmarks at present refreshed, for example, ISO 9001:2015 and ISO 14001:2015 Certification.

ISO 45001 Certification has been created with the mechanical and modernization improvements the health dangers and mishaps because of carelessness has been proceeding to build step by step. Because of this the demise rate keeps on being expanding step by step.

ISO 45001 empowers the association to show to their clients, laborers, controllers and the network that they proactively as efficiently deal with the health and security of their laborers.

ISO 45001 has been distributed on twelfth March 2018. ISO 45001 is the world’s first OHS worldwide Certification and gives accentuation on the dynamic support to limit mischief to laborers through Leadership and Participation, understanding the setting of the business making a move to oversee chance by following every one of the necessities of ISO 45001 Certification universal standard and getting certified.

why we get ISO 45001 certification?

ISO 45001 Certification is a great idea to show to your laborers, the network, your clients, controllers and other intrigued people your association’s pledge to giving a work environment where the danger of sickness or damage to your laborers, network, clients is wiped out or limited.

- ISO 45001 Assist in gathering corporate and statutory due perseverance prerequisites

- Execution and ISO 45001 Improves your capacity to oversee administrative consistence

- It Reduces the general expenses of episodes

- Diminish vacation and the expenses of disturbance to tasks

- Improve temporary worker the executives

- Help with gathering due perseverance necessities and help stay away from expenses related with punishments and case

- Decrease the expense of protection premiums

- Decrease non-appearance and representative turnover rates

- Be perceived for having accomplished a worldwide benchmark (which may thus impact clients who are worried about their social duty)

In combination, these measures will ensure that an organization’s reputation as a safe place to work will be promoted, and can have more direct benefits, such as:

- Improved ability to respond to legal compliance issues.

- Reduction in number of accidents/incidents

- Reduction in cost of disruptions by reduction in downtime.

- Reduced insurance cost

- Reduced iteration rate of employees

- Recognition for having achieved an international system certification which will influence the customers who are concerned about their social responsibilities.

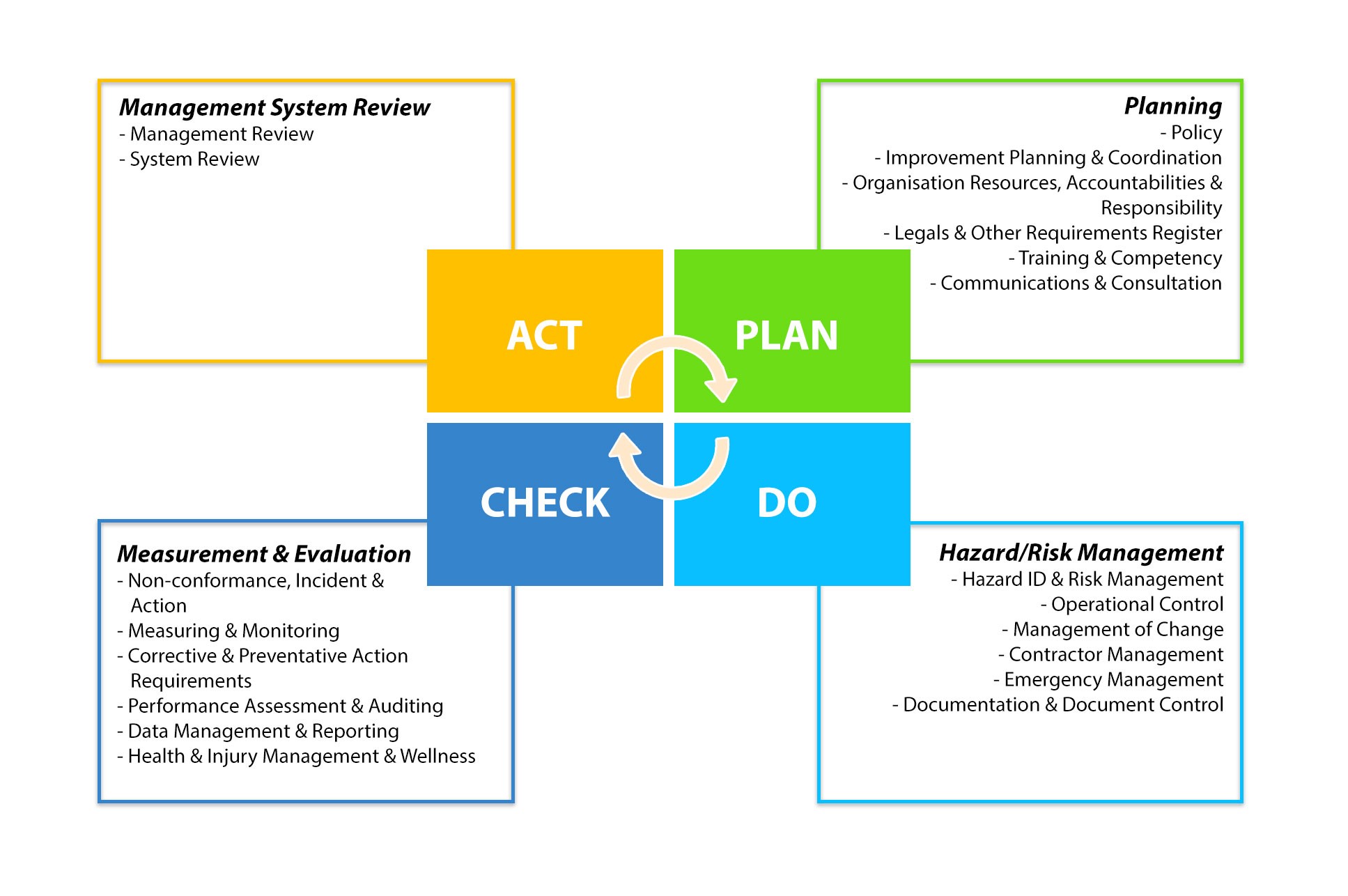

::PDCA Cycle::

Clause 1: Scope

Clause 1: Scope

This clause refers to the intent of ISO 45001, which is continual improvement of safety in organizations fulfilling legal requirements.

Clause 2: Normative references

This standard has no normative reference.

Clause 3: Terms & definitions

This clause provides the list of terms and definitions in ISO 45001.

Clause 4: Context of the Organization

| 4.1 Understanding the organization and its context |

| 4.2 Understanding the needs and expectations of workers and other interested parties |

| 4.3 Determining the scope of the OH&S management system |

| 4.4 OH&S management system |

Clause 5: Leadership and worker participation

| 5.1 Leadership and commitment |

| 5.2 OH&S policy |

| 5.3 Organizational roles, responsibilities and authorities |

| 5.4 Consultation and participation of workers |

Clause 6: Planning

| 6.1 Actions to address risks and opportunities |

| 6.1.1 General |

| 6.1.2 Hazard identification and assessment of risks and opportunities |

| 6.1.3 Determination of legal requirements and other requirements |

| 6.1.4 Planning action |

| 6.2 OH&S objectives and planning to achieve them |

Clause 7: Support

| 7.1 Resources |

| 7.2 Competence |

| 7.3 Awareness |

| 7.4 Communication |

| 7.4.1 General |

| 7.4.2 Internal communication |

| 7.4.3 External communication |

| 7.5 Documented information |

| 7.5.1 General |

| 7.5.2 Creating and updating |

| 7.5.3 Control of documented information |

Clause 8: Operation

| 8.1 Operational planning and control |

| 8.1.1 General |

| 8.1.2 Eliminating hazards and reducing OH&S risks |

| 8.1.3 Management of change |

| 8.1.4 Procurement |

| 8.1.4.1 General |

| 8.1.4.2 Contractors |

| 8.1.4.3 Outsourcing |

| 8.2 Emergency preparedness and response |

Clause 9: Performance Evaluation

| 9.1 Monitoring, measurement, analysis and performance evaluation |

| 9.1.1 General |

| 9.1.2 Evaluation of compliance |

| 9.2 Internal audit |

| 9.2.1 General |

| 9.2.2 Internal audit programme |

| 9.3 Management review |

Clause 10: Improvement

| 10.1 General |

| 10.2 Incident, nonconformity and corrective action |

| 10.3 Continual improvement |

Mandatory documents and records required by 45001:2018 OH&SMS

- Scope of the OH&S management system (clause 4.3)

- OH&S policy (clause 5.2)

- Responsibilities and authorities within OH&SMS (clause 5.3)

- OH&S process for addressing risks and opportunities (clause 6.1.1)

- Methodology and criteria for assessment of OH&S risks (clause 6.1.2.2)

- OH&S objectives and plans for achieving them (clause 6.2.2)

- Emergency preparedness and response process (clause 8.2)

- OH&S risks and opportunities and actions for addressing them (clause 6.1.1)

- Legal and other requirements (clause 6.1.3)

- Evidence of competence (clause 7.2)

- Evidence of communications (clause 7.4.1)

- Plans for responding to potential emergency situations (clause 8.2)

- Results on monitoring, measurements, analysis and performance evaluation (clause 9.1.1)

- Maintenance, calibration or verification of monitoring equipment (clause 9.1.1)

- Compliance evaluation results (clause 9.1.2)

- Internal audit program (clause 9.2.2)

- Internal audit report (clause 9.2.2)

- Results of management review (clause 9.3)

- Nature of incidents or nonconformities and any subsequent action taken (clause 10.2)

- Results of any action and corrective action, including their effectiveness (clause 10.2)

- Evidence of the results of continual improvement (clause 10.3)

- Procedure for Determining Context of the Organization and Interested Parties (clause 4.1)

- OH&S Manual (clause 4)

- Procedure for Consultation and Participation of Workers (clause 5.4)

- Procedure for Hazard Identification and Assessment (clause 6.1.2.1)

- Procedure for Identification of Legal Requirements (clause 6.1.3)

- Procedure for Communication (clause 7.4.1)

- Procedure for Document and Record Control (clause 7.5)

- Procedure for Operational Planning and Control (clause 8.1)

- Procedure for Change Management (clause 8.1.3)

- Procedure for Monitoring, Measuring and Analysis (clause 9.1.1)

- Procedure for Compliance Evaluation (clause 9.1.2)

- Procedure for Internal Audit (clause 9.2)

- Procedure for Management Review (clause 9.3)

- Procedure for Incident Investigation (clause 10.1)

- Procedure for Management of Nonconformities and Corrective Actions (clause 10.1)

- Procedure for Continual Improvement (clause 10.3)